Complete list of cylindrical lithium battery models, knowledge of cylindrical lithium batteries

Complete list of cylindrical lithium battery models:

| Cell Model | 18650-1300mAh | 18650-1300mAh | 26700-2600mAh | 26700-3000mAh | 26700-3200mAh | 32140-9000mAh | 32700-4700mAh | 40140-15000mAh |

| Nominal Voltage | 3.10V | |||||||

| Nominal Capacity | 1300mAh | 1300mAh | 2600mAh | 3000mAh | 3200mAh | 9000mAh | 4700mAh | 15Ah |

| Dimension | H*D=65.3*18.3mm | H*D=65.3*18.3mm | H*D=71*26.4mm | H*D=71*26.4mm | H*D=71*26.4mm | H*D=140.5*32.5mm | H*D=70.5*32.3mm | H*D=140.5*40.5mm |

| Inner Resistance | ≤20mΩ | ≤20mΩ | ≤20mΩ | ≤20mΩ | ≤20mΩ | ≤5mΩ | ≤15mΩ | ≤3mΩ |

| Weight | Appx. 30g | Appx. 30g | Appx.82g | Appx.82g | Appx.82g | Appx.250g | Appx.135g | Appx.390g |

| Cyle Life | ≥2000 times | ≥2000 times | ≥2000 times | ≥2000 times | ≥2000 times | ≥2000 times | ≥1500 times | ≥2000 times |

| Standard Charge Current | 0.5C | |||||||

| Standard Discharge Current | 0.5C | |||||||

| Max Con. Discharge Current | 20C | 5C | 20C | 5C | 3C | 3C | 3C | 5C |

| Pulse Discharge Rate | 25C | 15C | 30C | 8C | 5C | 9C | 8C | 10C |

| Dischage Cut-off Voltage | 2.0±0.05V | 1.50±0.05V | 2.0±0.05V | |||||

| Shape | Cylindrical | |||||||

| Charge Voltage | 3.95±0.05V | |||||||

| Battery Material | Sodium-ion | |||||||

| Charge Method | CC/CV | |||||||

| -20℃ Capacity retention | ≥90% | |||||||

| -40℃ Capacity retention | ≥70% | |||||||

| Charge Temperature | -10~45°C | |||||||

| Discharge Temperature | -40~80°C | |||||||

| Storage Temperature | Less than 1 year:-10~25°C; Less than 3 months:-10~40°C | |||||||

I. What is a cylindrical lithium battery?

1. Definition of cylindrical battery

Cylindrical lithium batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese mixture, and ternary materials. The outer shell is divided into two types: steel shell and polymer. Batteries of different material systems have different advantages. At present, the cylinder is mainly steel shell cylindrical lithium iron phosphate battery. This battery has high capacity, high output voltage, good charge and discharge cycle performance, stable output voltage, large current discharge, stable electrochemical performance, safe use, wide operating temperature range, and environmentally friendly. It is widely used in solar lamps, lawn lamps, backup energy, power tools, and toy models.

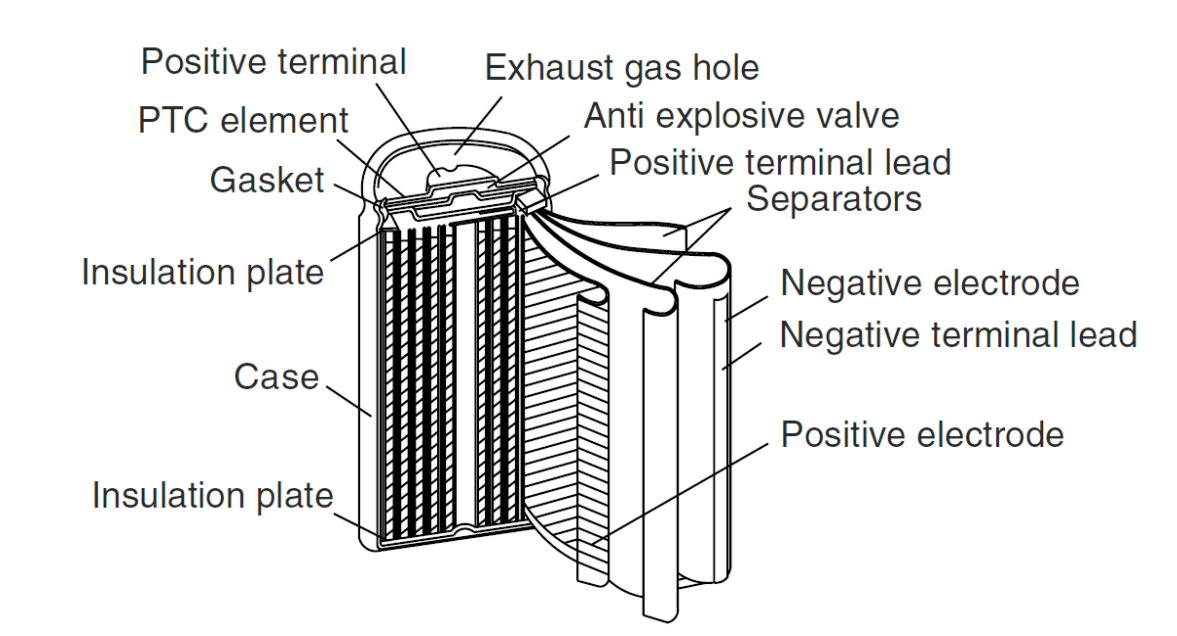

2. Cylindrical battery structure

The structure of a typical cylindrical battery includes: outer shell, cap, positive electrode, negative electrode, diaphragm, electrolyte, PTC element, gasket, safety valve, etc. Generally, the battery shell is the negative electrode of the battery, the cap is the positive electrode of the battery, and the battery shell is made of nickel-plated steel plate.

3. Advantages of cylindrical lithium batteries

Compared with soft-pack and square lithium batteries, cylindrical lithium batteries have the longest development time, high standardization, mature technology, high yield rate and low cost.

Complete list of cylindrical lithium battery models

I. What is a cylindrical lithium battery?

1. Definition of cylindrical battery

Cylindrical lithium batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt-manganese mixture, and ternary materials. The outer shell is divided into steel shell and polymer. Batteries of different material systems have different advantages. At present, the cylinder is mainly steel shell cylindrical lithium iron phosphate battery. This battery has high capacity, high output voltage, good charge and discharge cycle performance, stable output voltage, large current discharge, stable electrochemical performance, safe use, wide operating temperature range, and environmentally friendly. It is widely used in solar lamps, lawn lamps, backup energy, power tools, and toy models.

2. Cylindrical battery structure

The structure of a typical cylindrical battery includes: shell, cap, positive electrode, negative electrode, diaphragm, electrolyte, PTC element, gasket, safety valve, etc. Generally, the battery shell is the negative electrode of the battery, the cap is the positive electrode of the battery, and the battery shell is made of nickel-plated steel plate.

3. Advantages of cylindrical lithium batteries

Compared with soft-pack and square lithium batteries, cylindrical lithium batteries have the longest development time, high degree of standardization, mature technology, high yield rate and low cost.

·Mature production technology, low PACK cost, high battery product yield rate, good heat dissipation performance

·Cylindrical batteries have formed a series of internationally unified standard specifications and models, mature technology, suitable for large-scale continuous production.

·The specific surface area of the cylinder is large and the heat dissipation effect is good.

·Cylindrical batteries are generally sealed batteries, and there is no maintenance problem during use.

·The battery shell has high pressure resistance, and there will be no expansion of square and soft-pack batteries during use.

2. Cylindrical lithium battery cells

1. Cylindrical lithium-ion battery cell brands

Cylindrical lithium batteries are more popular among Japanese and Korean lithium battery companies, and there are also considerable companies in China that produce cylindrical lithium batteries. The earliest cylindrical lithium battery was invented by Japan's SONY company in 1992.

Well-known cylindrical lithium-ion battery cell brands: Sony, Panasonic, Sanyo, Samsung, LG, Wanxiang A123, BAK, Lishen, CSIT,etc.

2. Types of cylindrical lithium-ion batteries

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery height, and the fifth digit indicates a round shape. There are many models of cylindrical lithium batteries, the more common ones are 10400, 14500, 16340, 18650, 21700, 26650, 32650, etc.

①10440 battery

10440 battery is a lithium battery with a diameter of 10mm and a height of 44mm, which is the same size as what we often call "No. 7 battery". The capacity of this battery is generally very small, only a few hundred mAh, and is mainly used in mini electronic products. For example, flashlights, mini speakers, loudspeakers, etc.

②14500 battery

14500 battery is a lithium battery with a diameter of 14mm and a height of 50mm. This battery is generally 3.7V or 3.2V, with a relatively small nominal capacity, slightly larger than the 10440 battery, generally 1600mAh, with excellent discharge performance. The main application field is consumer electronics, such as wireless speakers, electric toys, digital cameras, etc.

③16340 battery

16340 battery is a lithium battery with a diameter of 16mm and a height of 34mm. This battery is shorter in height and has a relatively small capacity, so it often appears in high-intensity flashlights, LED flashlights, headlights, laser lights, lighting fixtures, etc.

④18650 battery

18650 battery is a lithium battery with a diameter of 18mm and a height of 65mm. Its biggest feature is that it has a very high energy density, almost reaching 170 watt-hours/kilogram. Therefore, this battery is a cost-effective battery. Most of the batteries we often see are of this type because it is a relatively mature lithium battery with good system quality stability in all aspects. It is widely used in battery capacity occasions of about 10 kWh, such as in, in mobile phones, laptops and other small appliances.

⑤21700 battery

21700 battery is a lithium battery with a diameter of 21mm and a height of 70mm. Because of its increased volume and increased space utilization, the energy density of the battery cell and the system can be improved. Its volume energy density is much higher than that of 18650 batteries. It is widely used in digital, electric vehicles, balance cars, solar energy lithium battery street lights, LED lights, power tools, etc.

⑥ 26650 battery

26650 battery is a lithium battery with a diameter of 26mm and a height of 65mm, a nominal voltage of 3.2V and a nominal capacity of 3200mAh. This battery has excellent capacity and high consistency, and has gradually become a trend to replace 18650 batteries. Many products in the field of power batteries will gradually favor this.

⑦ 32650 battery

32650 battery is a lithium battery with a diameter of 32mm and a height of 65mm. This battery has a strong continuous discharge capacity, so it is more suitable for electric toys, backup power supplies, UPS batteries, wind power generation systems, and wind-solar complementary power generation systems.

3. Cylindrical lithium battery market development

The technological progress of cylindrical lithium-ion batteries mainly comes from the innovative research and application progress of key battery materials. The development of new materials can further improve battery performance, improve quality, reduce costs, and improve safety. In order to meet the requirements of downstream applications for battery specific energy improvement, on the one hand, high specific capacity materials are adopted, and on the other hand, high voltage materials can be adopted by increasing the charging voltage.

Cylindrical lithium-ion batteries have developed from 14500 to Tesla 21700 batteries. In the near and medium-term development, while optimizing the existing lithium-ion power battery technology to meet the needs of large-scale development of new energy vehicles, we will focus on developing new lithium-ion power batteries, improve their key technologies such as safety, consistency and life, and simultaneously carry out forward-looking research and development of new system power batteries.

For the medium and long-term development of cylindrical lithium-ion batteries, while continuously optimizing and improving new lithium-ion power batteries, we will focus on developing new system power batteries, significantly improve specific energy, significantly reduce costs, and realize the practical application and large-scale application of new system power batteries.

IV. Comparison between cylindrical lithium batteries and square lithium batteries

1. Battery shape: The size of the square battery can be designed arbitrarily, while the cylindrical battery cannot be compared.

2. Rate characteristics: The process limitation of welding multi-pole ears for cylindrical batteries makes the rate characteristics slightly worse than that of square multi-pole ears.

3. Discharge platform: Theoretically, the discharge platform of lithium batteries using the same positive and negative electrode materials and electrolytes should be consistent, but the discharge platform in square lithium batteries is slightly higher.

4. Product quality: The manufacturing process of cylindrical batteries is relatively mature, the probability of secondary cutting defects in the pole pieces is low, and the maturity and automation of the winding process are relatively high. The stacking process is still semi-manual, which has an adverse effect on the quality of the battery.

5. Pole ear welding: The pole ears of cylindrical batteries are easier to weld than those of square lithium batteries; square lithium batteries are prone to false welding, which affects the quality of the battery.

6. PACK grouping: Cylindrical batteries are easier to use, so the PACK technology is simple and the heat dissipation effect is good; the heat dissipation problem must be solved when square lithium batteries are PACKed.

7. Structural characteristics: The chemical activity at the corners of square lithium batteries is poor, and the energy density of the battery is prone to decay after long-term use, and the battery life is short.

V. Comparison between cylindrical lithium batteries and soft-pack lithium batteries

1. Soft-pack batteries have better safety performance. Soft-pack batteries are structurally packaged with aluminum-plastic film. When safety problems occur, soft-pack batteries generally bulge and crack, instead of exploding like steel or aluminum shell batteries; they are better than cylindrical lithium batteries in safety performance.

2. The weight of soft-pack batteries is relatively light. The weight of soft-pack batteries is 40% lighter than that of steel-shell lithium batteries of the same capacity, and 20% lighter than that of cylindrical aluminum-shell lithium batteries; the internal resistance is small. The internal resistance of soft-pack batteries is smaller than that of lithium batteries, which can greatly reduce the self-consumption of batteries;

3. The cycle performance of soft-pack batteries is good, and the cycle life of soft-pack batteries is longer. The attenuation of 100 cycles is 4% to 7% less than that of cylindrical aluminum-shell batteries;

4. The design of soft-pack batteries is relatively flexible, the shape can be changed into any shape, it can be thinner, and it can be customized according to customer needs to develop new battery cell models. Cylindrical lithium batteries do not have this condition.

5. Compared with cylindrical lithium batteries, the shortcomings of soft-pack batteries are poor consistency, high cost, and easy leakage. High cost can be solved by large-scale production, and leakage can be solved by improving the quality of aluminum-plastic film.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish