What is cell balancing in batteries?

Seriously affects the service life of electric vehicles

Balancing technology is an effective means to solve the problem of inconsistent power batteries. Currently, there are two main technologies: active balancing and passive balancing. For the two balancing technologies of active balancing and passive balancing, the principles, circuit structures, control strategies, etc. are analyzed and compared, and the application design of the two balancing technologies in electric vehicle power batteries is given.

Active balancing and passive balancing two balancing technologies

At present, electric vehicles generally use lithium-ion power batteries. The capacity and voltage of their single cells vary greatly, which are prone to inconsistency during charging and discharging, resulting in a shortened driving range of electric vehicles and affecting the service life of the battery. At present, the power battery commonly used in electric vehicles is lithium iron phosphate battery.

Leading to shortened driving range of electric vehicles

Since lithium iron phosphate battery is a secondary battery, inconsistency will occur during the charging and discharging process. This is due to the different internal resistance and resistivity of lithium iron phosphate batteries. In order to solve this problem, it is necessary to balance the single cells to minimize the internal inconsistency as much as possible. Currently, there are two common balancing methods: active balancing and passive balancing.

It is necessary to balance the single cells.

Active balancing refers to balancing using a circuit structure composed of a circuit and a control chip. Unlike passive balancing, active balancing does not require changing the state of any other device or component, and has the advantages of simple implementation, low cost, and no impact on the battery.

Simple, low cost, and no impact on the battery.

However, due to the large resistance and capacitance differences between single cells, the active balancing circuit needs to transform the voltage of each cell to a uniform voltage value through a transformer, which requires adding a set of power switching devices between the switch tube, transformer, and control chip. In addition, since each cell needs to be synchronously sampled and controlled, the circuit structure is more complex and the cost is higher.

This requires adding a set of power switching devices between the switch tube, transformer, and control chip.

Passive balancing refers to converting the voltage of each cell without changing the battery state, and then comparing the converted voltage values. This method is mainly achieved by detecting the difference between the voltages of each cell.

Comparison of converted voltage values

Compared with active balancing, passive balancing requires changing the state of other devices or components, which increases the complexity and cost of the circuit. In addition, since the difference in voltage of each cell needs to be detected to achieve balance, an additional acquisition system is required; if the internal resistance and resistivity of the cell are to be detected, an energy acquisition module is also required.

In addition, since the difference in voltage of each cell needs to be detected to achieve balance, an additional acquisition system is required

Since the voltage and internal resistance of each cell need to be measured, a control system is also required.

Balance technology refers to adjusting the voltage difference between cells to adjust the inconsistent voltage, capacity, resistance and other parameters generated by the battery during the charging and discharging process from large to small to keep the battery working in the best state and reduce problems such as shortened battery life caused by differences in the performance of cells.

Voltage, capacity, resistance and other parameters

Due to the simple structure and low cost of traditional passive balancing technology, it is currently the main way to balance the power battery of electric vehicles.

Simple structure and low cost

Active balancing technology charges or discharges the cells so that the voltage difference of each cell reaches the set value or keeps it within a certain range to maximize the performance of lithium-ion power batteries. The most commonly used active balancing technology is series-parallel technology.

Make the voltage difference of each single cell reach the set value or keep it within a certain range to maximize the performance of lithium-ion power batteries

In the series circuit, each single cell works alone, but when the lithium-ion power battery is fully charged, the single battery pack will remain in a stable state, which is the so-called "rest period". During this period, the voltage in the battery pack does not change and remains constant.

However, when the lithium-ion power battery is fully charged, the single battery pack will remain in a stable state

When the capacity of a single cell in the battery pack drops to a certain value, it will cause the voltage of other single cells to drop or even become a "floating charge" state. When all single cells are in this "rest period", the voltage in the battery pack will remain at a constant value.

Battery capacity

Passive balancing technology uses the heat generated by lithium-ion power batteries during charging and discharging to achieve balancing. Passive balancing technology does not require any energy input when used, and achieves balancing by monitoring the temperature changes inside the lithium-ion power battery.

Heat to achieve balancing

When lithium-ion power batteries generate heat during operation, active balancing technology can cool them down in a timely and effective manner.

Active balancing technology can cool it down in time and effectively.

Passive balancing technology can keep the battery pack running in a stable state at any time. When a single cell in the battery pack fails, other single cells can still work normally;

When a single cell in the battery pack fails, the other single cell will not be affected. Active balancing technology requires all single cells in the entire battery pack to be connected to the circuit for charging or discharging operations.

The other single cell will not be affected

The advantages of active balancing technology are its simple structure, low cost, high charging and discharging efficiency, and high energy utilization; its disadvantage is that the life of the battery pack is greatly affected by multiple cells.

Simple structure, low cost, high charging and discharging efficiency, high energy utilization

Passive balancing technology can connect all single cells in the battery pack to the circuit for charging or discharging operations at any time, so balancing can also be achieved when there are multiple inconsistent cells in the battery pack.

Active balancing technology has a complex structure and high cost; passive balancing technology has a simple structure and low cost. Active balancing technology is much more complicated to manage battery packs than passive balancing technology.

Simple technical structure and low cost

Active balancing technology needs to collect information such as voltage, current, temperature, etc. of each cell; while passive balancing technology only needs to collect information of a cell in the battery pack to achieve balancing.

Voltage, current, temperature, etc.

ï¼›

The combination of active balancing and passive balancing in electric vehicle power batteries can effectively solve the inconsistency problem between cells, thereby extending the service life of the battery. This paper uses active balancing technology to balance lithium-ion battery cells.

It can effectively solve the inconsistency problem between cells

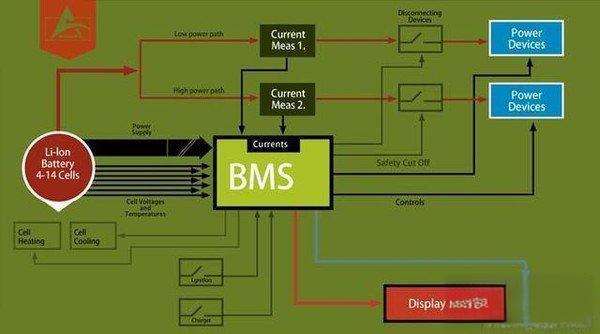

The active balancing control circuit consists of a main controller, a passive balancing circuit, and a signal acquisition module. Among them, the main controller is the core of the entire system. Its function is to control the working state of the passive balancing circuit, realize the collection and processing of battery voltage and capacity information, and make judgments and controls.

Main controller, passive balancing circuit, signal acquisition module

The passive balancing circuit consists of a balancing switch, a bidirectional IGBT driver, etc. The main function is to drive and isolate the cells in the battery pack through a unidirectional IGBT to realize bidirectional energy transmission, so that the voltage and capacity of the cells in the battery pack are as close to the same as possible.

Balance switch, bidirectional IGBT driver, etc.

The single cells in the power battery pack have an initial state of charge (SOC) value. During use, the single cells will age and be damaged to a certain extent, causing the SOC value to change. According to the change of SOC value, the battery pack can be divided into four categories: normal, healthy, aged, and unhealthy.

Cause SOC value changes

Since the SOC value of each type of battery is different, in order to better manage each single cell in the battery pack, active balancing technology can be used to control it. In active balancing, since the passive balancing circuit works unidirectionally, the battery pack can be divided into two or more groups for control.

In order to better manage each single cell in the battery pack

When a group of single cells is in a healthy state (SOC value is close to 1), the battery is isolated from the battery pack; when a group of single cells is in an unhealthy state (SOC value is less than 1), the battery is isolated from the battery pack.

(SOC value is close to 1)

(SOC value is less than 1)

Based on the basic working principle of active balancing technology and the current use of electric vehicle power batteries, the following methods can be used to achieve balanced control of single cells in the battery pack:

Active balancing technology

(1) Current transfer method. This method is to distribute the voltage of single cells according to the voltage change of the power battery system and the deviation between the voltages of different single cells.

Voltage change

The current transfer method can isolate unhealthy batteries, avoiding excessive concentration of SOC values on a certain cell and affecting the voltage values of other single cells. This method requires an additional circuit to realize the current transfer function.

SOC value is less than 1

This method controls the voltage of the single power battery pack in the battery pack by converting the voltage of the unhealthy single cell into a certain voltage level. This method requires an additional conversion circuit, which is usually used in series battery packs.

Conversion circuit

(2) Power control method. This method controls the voltage of the unhealthy single power battery pack by controlling the power of the healthy cells isolated from the single cell pack. This method can use a control circuit to complete the control of the voltage of all single power battery packs in the battery pack.

A control circuit can complete the control of the voltage of all single power battery packs in the battery pack

(3) Balancing switch method. This method controls the voltage of each single battery in the power battery pack according to the voltage deviation between the single batteries, so that it reaches a constant value, thereby ensuring that the voltage of each single battery in each single power battery pack is at the same level under unbalanced conditions.

Constant value

This method controls the voltage of unhealthy and unhealthy single power battery packs according to the working characteristics of different types of lithium-ion batteries.

From a structural point of view, passive balancing is to connect inconsistent power battery cells in series to achieve battery voltage and capacity balance; while active balancing is to connect inconsistent power battery cells in series to achieve capacity and voltage balance.

Series connection

The active balancing structure is simple and the cost is low, but it requires an external energy source, which increases the cost and volume, and due to the inconsistent voltage in the battery pack, it is easy to cause the battery pack to be unbalanced;

The cost is low,

The passive balancing structure is simple and the cost is high, but its energy loss is small, the volume is small, there is no mechanical loss, and the impact on the performance of the battery itself is small.

The energy loss is small, the volume is small, there is no mechanical loss, and the impact on the performance of the battery itself is small.

From the circuit structure, the passive balancing circuit structure is simple, and the same chip can be used to uniformly control the battery pack, which is easy to maintain; the active balancing circuit structure is complex, because it requires an external energy source for energy transfer and output balance control, so it is easy to have abnormal conditions such as excessive or too low voltage during energy transfer.

The same chip can be used to uniformly control the battery pack

As a strategic industry that my country focuses on developing, new energy vehicles are an important force for my country to achieve the "two centenary" goals and the Chinese dream of the great rejuvenation of the Chinese nation, but it also brings some problems that cannot be ignored.

The important force of the "two centenary" goals and the Chinese dream of the great rejuvenation of the Chinese nation

For example, the use of new energy vehicle power batteries is prone to inconsistency problems, which seriously affects their service life. In order to solve this problem, there are mainly two research directions:

On the one hand, it is necessary to develop a new battery balancing system. By analyzing the working principle, circuit structure, control strategy, etc. of the battery balancing system, find out the factors affecting battery balancing and solve them. At the same time, study the impact of battery inconsistency on the service life of power batteries and improve battery life.

By analyzing the working principle, circuit structure, control strategy, etc. of the battery balancing system, find out the factors affecting battery balancing and solve them

By analyzing and processing the operating data of electric vehicles, the power battery is intelligently managed. Charge or discharge the power battery according to different situations to ensure that the power battery operates in the optimal state. At the same time, by analyzing and processing the battery pack data, the SOC algorithm and charging and discharging strategy are used to perform real-time balancing control of the battery pack.

Ensure that the power battery operates in the optimal state

Active balancing and passive balancing are two effective means to solve the problem of inconsistent power batteries. Active balancing has better working characteristics, but the circuit structure is complex and the cost is high; passive balancing circuit structure is simple, but it is easily affected by other factors and has poor working stability.

The circuit structure is complex and the cost is high; the passive balancing circuit structure is simple, but it is easily affected by other factors and has poor working stability.

Compared with BMS based on passive balancing, BMS based on active balancing has an advantage in price. Therefore, the application of active balancing technology in electric vehicles can achieve better economic benefits.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish