How Lithium Batteries Are Made

Lithium batteries are an important driving force of modern technology. From smartphones to electric cars, almost all portable devices rely on lithium batteries. However, the manufacturing process of lithium batteries is complex and full of technical challenges. It involves multiple stages and sophisticated processes, which determine the performance and life of lithium batteries. In this article, I will take a deep look at the manufacturing process of lithium batteries and share my views on the future development of this field.

Basic Structure of Lithium Batteries

Before exploring the manufacturing process of lithium batteries, let's first understand its basic structure. Lithium batteries are mainly composed of four parts: positive electrode, negative electrode, electrolyte and separator.

Positive electrode material: usually made of lithium metal oxide (such as LiCoO2, LiFePO4), responsible for storing and releasing lithium ions.

Anode material: usually graphite, the main function is to receive lithium ions released from the positive electrode.

Electrolyte: lithium salt dissolved in an organic solvent, as a medium for lithium ions to move between the positive and negative electrodes.

Separator: used to separate the positive and negative electrodes, prevent them from direct contact, avoid short circuit, and allow lithium ions to pass through.

After understanding these basic components, we can better understand each step in the manufacturing process.

Key steps in the lithium battery manufacturing process

The manufacturing of lithium batteries can be divided into the following key steps, each of which is crucial and has a direct impact on the performance and safety of the battery.

1. Preparation of positive and negative electrode materials

The preparation of positive and negative electrode materials is the starting point of the entire manufacturing process. The positive electrode material is usually mixed with a lithium compound and a conductive agent, and then coated on an aluminum foil substrate through a coating process. The negative electrode material is mostly made of natural graphite or artificial graphite, which is also coated on a copper foil substrate through a similar coating process. The coated electrode material needs to be dried and compacted to ensure that the density and thickness of the material are uniform, thereby improving the energy density and consistency of the battery.

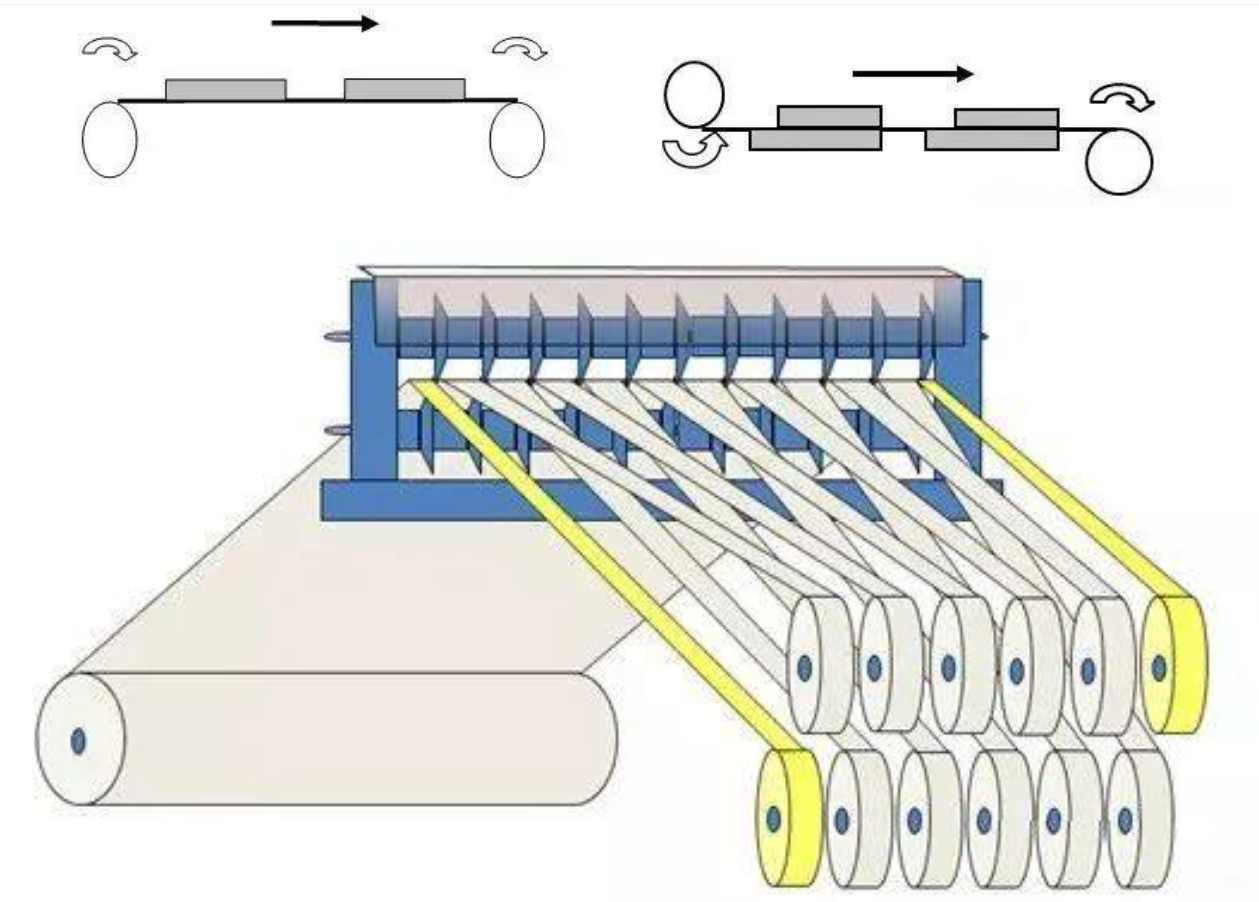

2. Assembly of electrodes

The dried electrode material is cut into specified sizes and then wound or laminated. The winding process is usually used for cylindrical or soft-pack batteries, while the stacking process is common in square batteries. In this process, the electrodes and separators are alternately stacked to form the basic structure of the battery.

3. Liquid injection

The assembled battery structure is placed in a closed shell, and the electrolyte is injected into the battery by vacuum injection. The injection amount and uniformity of the electrolyte directly affect the performance and life of the battery, so this process needs to be carried out under strictly controlled conditions.

4. Packaging and molding

After the injection is completed, the battery shell is sealed and a preliminary molding process is performed. The packaging process is usually carried out in an inert gas environment to prevent the electrolyte from reacting with moisture or oxygen in the air and affecting the stability of the battery.

5. Formation and capacity separation

The packaged battery needs to go through a process called "formation". Formation refers to the formation of a solid electrolyte interface (SEI) film on the surface of the electrode material during the first charge and discharge cycle of the battery. This film is crucial for protecting the electrode material and preventing the decomposition of the electrolyte. After formation, the battery enters the capacity classification stage, and is classified according to the difference in battery capacity to ensure the consistency of the battery pack.

Future development direction of lithium battery manufacturing

Although lithium battery technology has made significant progress in the past few decades, there are still some key areas that need to be improved, which can not only improve the performance of lithium batteries, but also promote the development of green manufacturing.

1. Material innovation

Currently, researchers are exploring new positive and negative electrode materials, such as silicon anodes and solid electrolytes. These materials are expected to significantly improve the energy density and safety of lithium batteries. However, the application of these materials still faces manufacturing process challenges, especially in large-scale production.

2. Intelligent manufacturing

The lithium battery manufacturing process involves a lot of complex process control and quality inspection. In the future, intelligent manufacturing technologies (such as artificial intelligence and big data analysis) will play a greater role in battery production, improving production efficiency and product quality through real-time monitoring and optimization of production parameters.

3. Sustainable development

With the improvement of environmental awareness, the recycling and reuse of lithium batteries has become an important issue. Green improvements in the manufacturing process, such as reducing the use of solvents and reducing energy consumption, will become industry standards in the future. In addition, developing efficient recycling processes that can recycle and reuse key materials such as lithium and cobalt is essential to reducing resource consumption and environmental impact.

The manufacturing process of lithium batteries is not just a simple combination of materials, but a complex and sophisticated engineering. With the advancement of science and technology, lithium battery manufacturing technology is also constantly developing. The application of new materials, the introduction of intelligent manufacturing and the promotion of sustainable development will make lithium batteries play a more important role in the future.

We also need to realize that lithium battery manufacturing still faces many challenges, such as improving energy density, reducing manufacturing costs, and reducing environmental impact. Solving these problems requires not only technological progress, but also collaborative innovation of the entire industry chain and joint efforts of society.

Looking to the future, lithium battery technology will continue to promote the transformation of the global energy structure and contribute to the goal of achieving sustainable development.

The above is an in-depth discussion of the manufacturing process of lithium batteries and sharing of views on the future development of this field. CSIT lithium battery manufacturer specializes in the production of sodium ion batteries and lithium ion battery packs. It can be customized and wholesaled according to user needs. If you have any needs, you can contact us and leave a message: sales01@csit-energy.com

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish