Ranking of lithium iron phosphate battery manufacturers, lithium iron phosphate battery brand characteristics

Overview of lithium iron phosphate battery

Lithium iron phosphate batteries are lithium ion batteries that use lithium iron phosphate as the cathode material. Lithium iron phosphate battery has the advantages of high safety, long cycle life, high temperature resistance, etc. It is considered a new generation of lithium battery. CSIT can provide customers with battery customization solutions integrating battery cell, BMS (power management system) and structure to meet customers' personalized power needs.

1. lithium iron phosphate battery features:

Good safety performance, puncture does not explode, overcharge does not burn or explode;

Good cycle life, lithium iron phosphate battery cycle life of up to 10000 times;

Good high temperature performance, working temperature range -20 ℃ to 70 ℃;

High vibration density, higher capacity under the same conditions;

1C-5C fast charging ability, greatly shorten the charging time.

2. Applications:

Power storage, special equipment, robotics, AGV, rail transportation, medical equipment, emergency backup, power communication, etc.

China lithium iron phosphate battery manufacturers

![]()

Lithium iron phosphate battery advantages:

1. Good safety performance

Safety comes from the stability of the cathode material and reliable safety design, lithium iron phosphate battery packs have been subjected to rigorous safety tests, even in violent collisions will not produce an explosion.

2. Long cycle life

Lithium iron phosphate battery cycle life is generally up to 10,000 times, higher than other types of lithium batteries.

3. High temperature performance

Lithium iron phosphate battery thermal peak up to 350 ~ 500 ℃, a wide range of operating temperatures (-20 ~ +75 ℃), high temperature (60 ℃) can still put out 100% capacity.

4. Fast charging

Using a special charger, 1.5C charging can make the battery full in 40 minutes.

5. Green

Lithium iron phosphate battery is green, non-toxic, non-polluting, with a wide range of raw materials and cheap price.

Lithium iron phosphate battery voltage and capacity:

1. Lithium iron phosphate battery voltage

The nominal voltage of single lithium iron phosphate battery is 3.2V, charging voltage is 3.6V, and the discharge cut-off voltage is 2.0V. lithium iron phosphate battery packs are combined in series through the cell to achieve the voltage required by the equipment, the battery pack voltage = N * the number of series connection. Commonly used lithium iron phosphate battery pack voltages are as follows:

12V lithium iron phosphate battery

24V lithium iron phosphate battery

2, lithium iron phosphate battery capacity

The capacity of lithium iron phosphate battery pack is based on the capacity and number of cells connected in parallel to determine, generally based on the specific requirements of the power equipment to determine the more lithium iron phosphate cells connected in parallel, the greater the capacity. Common lithium iron phosphate battery pack capacity of 10ah, 20ah, 30ah, 50ah, 100ah, 200ah, and so on.

Lithium iron phosphate battery structure and working principle:

1. Lithium iron phosphate battery structure

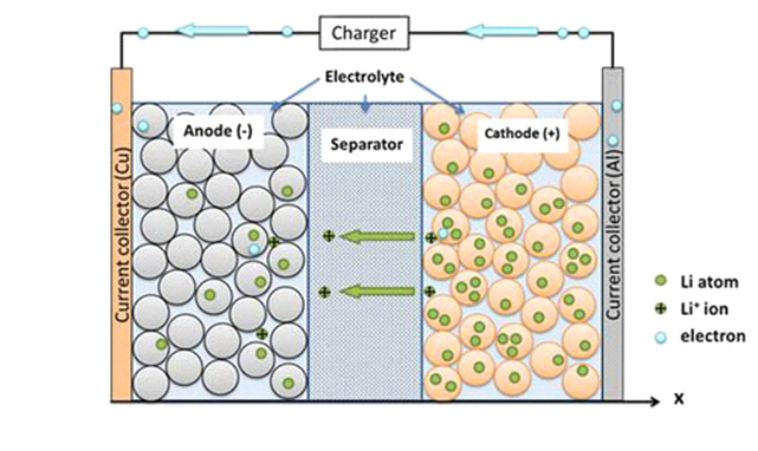

As shown in the figure, the left is the olivine structure of LiFePO4 as the positive electrode of the battery, connected with the positive electrode of the battery by the aluminum foil, in the middle of the polymer diaphragm, which separates the positive electrode from the negative electrode, but the lithium ions Li+ can pass through and the electrons can not be passed, the right is the negative electrode of the battery composed of carbon (graphite), connected with the negative electrode of the battery by the copper foil.

2. Lithium iron phosphate battery working principle

LiFePO4 battery in charging, the positive electrode in the lithium ion Li + polymer diaphragm to the negative electrode migration; in the discharge process, the negative electrode in the lithium ion Li + through the diaphragm to the positive electrode migration. Lithium-ion batteries are named for the back and forth migration of lithium ions during charging and discharging.

Lithium iron phosphate battery charger:

1. LiFePO4 Battery Charging

LiFePO4 battery charging is recommended to use CC/CV charging method, i.e. constant current followed by constant voltage. Constant current is recommended to be 0.3 C. Constant voltage is recommended to be 3.65.

2. Lithium iron phosphate battery and lithium ion battery charger the same?

Both battery charging method is first constant current and then constant voltage (CC/CV), but the constant voltage point is not the same.

The nominal voltage of lithium iron phosphate battery is 3.2V, charging cut-off voltage 3.6V.

The nominal voltage of ordinary lithium battery is 3.6V, and the charging cut-off voltage is 4.2V.

3, charging lithium iron phosphate batteries with solar energy

Solar panels can not be directly connected to the lithium iron phosphate battery charging, because the voltage of the solar panel is unstable, can not be directly to the lithium iron phosphate battery charging,need to add voltage regulator circuit, but also to support the corresponding lithium iron phosphate battery charging circuit to charge.

4. With a generator to lithium iron phosphate battery charging

Generator can not be directly connected to the lithium iron phosphate battery charging, because the generator sends out electricity for the alternating current or pulse DC, lithium iron phosphate battery charging must be regulated DC.

Lithium iron phosphate battery cycle life and the factors that affect it

1. Lithium iron phosphate battery used at room temperature environment

Small current charge and discharge

In this field of application of lithium iron phosphate battery normal use, basically more than 2000 times the cycle life;

High rate of stable charge and discharge use

The application of high rate discharge, most of the power lithium batteries, most of which are used to provide power to the motor application. As most of the lithium iron phosphate batteries are operated under high load conditions, which accelerates the decay time of the battery material, the cycle life is also around 800 times.

High rate unstable charging and discharging use

Lithium iron phosphate battery used in this case, the life will be even shorter, only about 300 times.

2. Lithium iron phosphate battery used in high temperature environment

Lithium iron phosphate battery high temperature performance is not very mature, operating temperature is from -20 ℃ to 70 ℃.

Small current charging and discharging

In this field of application on the normal use of lithium iron phosphate batteries, if the battery brand manufacturers are stronger, good quality, basically more than 1,000 times the cycle life; small lithium battery manufacturers, the quality of a little less than 500 times the cycle life; because the use of high temperatures, the damage to the battery is relatively large.

Stable charging and discharging at high rate

As most of the lithium iron phosphate batteries run under high load conditions, accelerating the decay time of the battery material, cycle life is a sharp decline in the poor quality of the battery cell, may also be about 300 times the cycle; the strength of the battery brand manufacturers, in the application of equipment technology and materials will be better, the quality of the battery cell will be better, but the cycle life of about 500 times.

High multiplier unstable charging and discharging use

High temperature plus discharge rate is not stable operation, more damage to the battery, the cycle life is relatively low, several battery manufacturers to do testing of electric cells found that 250 to 300 times, the battery basically can not be used.

3, lithium iron phosphate batteries used in low-temperature environment

Low-temperature environment on the lithium iron phosphate battery performance than the high but also large, the current market situation, lithium iron phosphate battery below -20 ° C to -40 ° C work, life expectancy decreased significantly, cycling

Lithium iron phosphate battery cycle life factors

Charge and discharge

When choosing a charger, it is best to use a charger with the correct termination of the charging device to cut off the charger, so as not to shorten the service life of lithium iron phosphate battery due to overcharging. Generally speaking, slow charging is better than fast charging to extend the service life of the battery.

Depth of discharge

The depth of discharge is the main factor affecting the life of lithium iron phosphate battery, the higher the depth of discharge, the shorter the life of lithium iron phosphate battery. In other words, as long as the depth of discharge is reduced, the service life of LiFePO4 battery can be greatly extended. Therefore, we should avoid over-discharging lithium battery UPS to very low voltage.

Working environment

If the lithium iron phosphate battery is used for a long time under high temperature, it will make its electrode activity decay and shorten its service life, so try to keep it in the appropriate operating temperature is to extend the life of lithium iron phosphate battery.

Recycling of lithium iron phosphate batteries:

Retired lithium iron phosphate batteries do not have the value of stepwise utilization of batteries and stepwise utilization of batteries will eventually enter the dismantling and recycling stage. Lithium iron phosphate batteries and ternary material batteries are different, does not contain heavy metals, recycling is mainly Li, P, Fe, recycling products with low added value, the need to develop low-cost recycling routes. There are mainly two types of recycling methods: pyrotechnic method and wet method.

Fire recovery process

The traditional pyro-recovery generally involves high temperature incineration of electrode pieces to burn off the carbon and organic matter in the electrode fragments, and the remaining ash that cannot be burned off is eventually screened to obtain fine powdery materials containing metals and metal oxides.

Wet Recovery Process

Wet recycling is mainly through the acid and alkali solution to dissolve the metal ions in lithium iron phosphate batteries, and further use of precipitation, adsorption and other ways to dissolve the metal ions in the form of oxides, salts and other forms of extraction, the reaction process most of the use of H2SO4, NaOH and H2O2 and other reagents.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish