What are the advantages and disadvantages of cylindrical batteries, square batteries and flexible pack batteries?

Lithium batteries can be categorized into cylindrical batteries, square batteries and soft pack batteries according to the package form. Although the current market of power batteries, square batteries as the mainstream, but between the three kinds of batteries have their own advantages and disadvantages.

Cylindrical batteries, in the field of power batteries impressive is the Tesla. From 18650 to 21700, and then to the upcoming mass production of 46800 batteries, basically Tesla is leading the trend.

Take 18650 battery as an example, 18 represents the diameter of the battery, 65 represents the height of the battery, and 0 represents that it is a cylindrical battery, so 27100 and 46800 are naturally the same.

18650 battery is the earliest development of lithium battery package form, in 1992, the cylindrical battery has been greater development. Initially, 18650 batteries were mostly used in digital products.

Because of the first-mover advantage, the cylindrical battery is the most mature form of packaging technology. Specifically, 18650 has a higher yield rate, and the cost of PACK can be effectively controlled.

Compared to square hard shell batteries, cylindrical battery space utilization is insufficient, but cylindrical batteries can use the gap in the middle of the cylinder to circulate coolant, is also considered a kind of space utilization.

Disadvantages, 18650 disadvantages can not be ignored, a 18650 battery using a metal shell plus a smaller capacity of the single battery, in order to meet the capacity requirements can only be made up by the number of substantial additions, then a larger number of BMS battery management system about the requirements of higher.

Square battery is currently the most widely used battery in the field of lithium. Domestic mainstream BYD, Geely, Azure and a series of new energy vehicle enterprises are using square hard shell batteries, and international traditional manufacturers such as Audi, BMW, etc. are also using square battery solutions.

One of the most important reasons for the wide application of square batteries is that there are more suppliers and the technical difficulty is relatively low, the vast majority of domestic battery suppliers have chosen to develop square batteries. For example, the famous Ningde Times, BYD, Guoxuan Gaoke, etc. are important suppliers of square hard shell battery.

Square battery advantage in addition to the rich suppliers, it can be customized to a higher degree, at the same time square space utilization rate relative to cylindrical batteries is also higher, but the problem is that the outer hard protective shell will obviously add the overall weight of the battery pack, so the domestic similar to the ideal manufacturing ONE have begun to aluminum as the outer protective shell, effectively ensure lightweight and thus enhance the energy density of the battery.

At the same time, square battery capacity and volume of the single unit are larger, the number of single unit naturally reduced, then the requirements on the BMS battery management system is also lower. At present, the most representative square hard shell motor is NCM811 battery launched by Ningde Times.

The disadvantage of square batteries is the high degree of freedom of customization, resulting in the manufacturing process is not uniform, the differences between each battery will be highlighted. Related to cylindrical batteries, square hard shell batteries have higher requirements regarding the cooling system arrangement. However, with the launch of the national policy on battery standards, the differences in the future of square batteries will also be reduced.

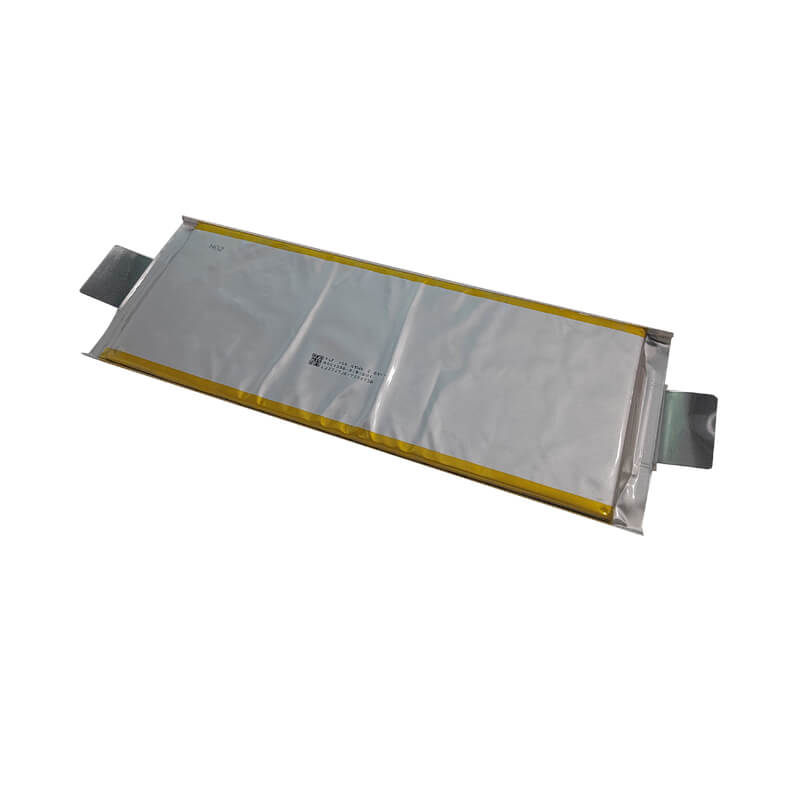

Soft pack battery although the application in the automotive market is becoming more and more, because the lithium battery in the cell phone, its package form is mostly soft pack battery, so we are not unfamiliar with it.

The shell of the soft pack battery is made of aluminum-plastic film, which is lighter in weight compared to square and cylindrical batteries with aluminum shells. Under the same capacity, the weight of the soft pack battery is 20% lighter, and under the same weight, the capacity of the soft pack battery is 50% higher than the aluminum shell battery.

Therefore, the theoretical energy density of soft pack batteries is higher than that of square and cylindrical batteries. In terms of shortcomings, soft pack batteries currently need to solve the problems of standardization and high cost, high-end aluminum-plastic film is heavily dependent on imports, poor consistency and so on.

CSIT lithium battery manufacturers believe that soft pack batteries have great potential and will become the mainstream of the future.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish