Lithium Batteries:Differences,Uses,and How to Choose the Best Lithium Batteries Lithium Batteries:

Differences,Uses,and Choices for Industrial Applications

In this article,we will analyze the lithium battery formats on the market and understand which ones are best suited for industrial applications.One of the basic elements of lithium batteries is undoubtedly the cells that make them up.

There are three most popular forms of lithium batteries currently produced:

Cylindrical battery

Soft pack battery

prismatic battery

Cylindrical battery

The cylindrical cells used in lithium batteries are very similar to those in our home remote controls.The most common format is 18650(diameter 18 mm,height 650 mm),but there are other formats such as 21700,26650,or there are custom solutions chosen by the CSIT lithium battery manufacturers themselves.

Advantages of cylindrical batteries:

The advantage of using cylindrical lithium batteries is that the shell is strong and the chemical composition can be changed while keeping the mechanics of the containment unchanged.

Disadvantages of cylindrical batteries:

The disadvantage of cylindrical lithium batteries is that the single battery capacity is low,up to 3Ah,and the batteries are welded and assembled in series and parallel.

This type of construction does not allow the replacement of individual cells,but requires the replacement of the entire module through more invasive and expensive interventions.If your industrial vehicle reports battery issues,you will have to replace the entire module,resulting in costly downtime.

In addition,the low capacity of a single component and the consequent"parallel connection"of many components often leads to a decrease in the safety of the entire lithium battery pack.

Most lithium battery assemblers operate in parallel.batteries to achieve the required capacity,for example if you need a capacity of 200 Ah and use a 2.5 Ah battery you will have to connect 80 cells in parallel,all of them in parallel.If one of them fails due to an internal problem due to a short circuit not only will its energy be absorbed,but all the energy of its 80 cylindrical cells connected in parallel will have to be dissipated.

This phenomenon may be converted into very high heat on the module side,and may also cause catastrophic consequences such as fire.

To avoid this,large manufacturers like CSIT use very complex production processes that allow the use of a fuse to connect batteries in parallel.If the battery shorts out,the"fuse"will blow and the battery pack will still be safe.

Unfortunately,no lithium battery manufacturer in the industrial market has these technologies.These negative factors lead us to avoid this type of battery in flash batteries.

Soft pack battery

Pouched lithium batteries are named for their packaging/envelope shape,and their dimensions vary greatly depending on the manufacturer's construction choices.

Advantages of soft pack batteries

The advantage of this lithium technology is that it can achieve high energy density and low-cost housing.There are pouch batteries from a few hundred mAh to 20Ah on the market,and few manufacturers have surpassed this threshold

Disadvantages of soft pack batteries

The most negative aspect is of course the fragility of this shell,it only takes a very small amount of time to damage it,and even the use of a fingernail can cause irreparable damage to it.

When using this type,the cell packaging system is very important as it must protect the individual cells from any type of stress:vibration,crushing and deformation.

The unit packaging system used to create modules is very important,so creating custom modules is complicated,if not impossible.

These batteries always have low to medium capacity.

In order to manufacture industrial battery packs,dozens of batteries need to be connected in parallel,which reduces the safety of the battery pack.Also in this case,the individual cells are welded to connect in series or parallel,so it is impossible to replace the cells,the entire module must be replaced.

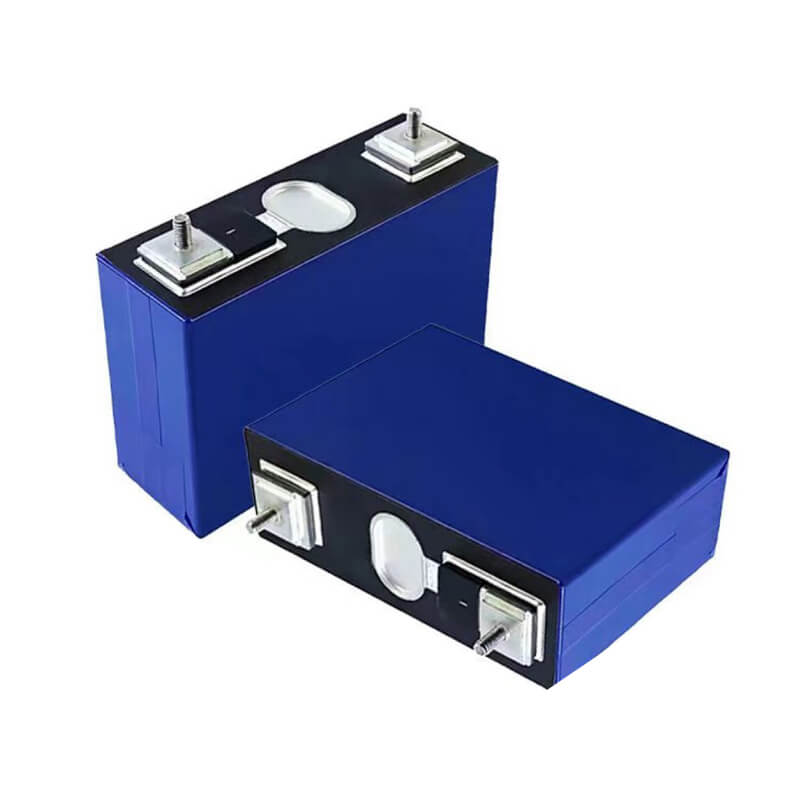

Prismatic battery:

Prismatic lithium batteries have a solid casing,usually made of plastic or metal(aluminum),and have screw or solder terminals

Advantages of prismatic batteries:

The prismatic battery casing is very strong,making it ideal for custom battery packs,avoiding complex studies of mechanical stress and expensive testing.

The high capacity of a single component,a single cell can reach 300Ah,is highly appreciated in the manufacture of batteries with important capacities such as those in the industrial market.Avoiding parallel cells significantly improves the safety of the entire battery pack.

Another important aspect is the screw,which simplifies assembly and makes any component replacement operations easy,even on site.

Disadvantages of prismatic batteries:

The disadvantage of prismatic lithium batteries is that their high energy density is slightly lower due to the type of casing.

About information about lithium batteries,we can say:

Cylindrical cells are usually used in small lithium batteries(<2kWh),such as electric bicycles,screwdrivers,gardening tools,etc.),only Tesla uses them in the automotive field

Soft-pack batteries are mainly produced using NMC chemistries and are particularly used in high-power applications(high voltage and low capacity)or applications that require a reduced footprint,such as electric motorcycles or electric cars.

Prismatic batteries are used in lithium batteries in the industrial and automotive fields to manufacture medium to large size battery packs.

The best lithium battery for your industrial machines

Precisely because of its characteristics,we choose prismatic batteries as flash memory batteries.

They enable us to achieve high-quality performance for applications in industrial machinery and electric vehicles.

To learn more about our technology,please email sales at 01.csit gmail.com.

简体中文

简体中文 Russian

Russian French

French German

German Japanese

Japanese Korean

Korean Arabic

Arabic Spanish

Spanish